A driver is on a critical, time-sensitive delivery. At a roadside inspection, the elog freezes. The officer is waiting, dispatch is on hold, and the driver’s entire Hours of Service (HOS) log is suddenly in question.

This scenario is a common frustration. The ELD mandate digitized HOS, but it also brought new operational hurdles. While compliance rates are high, drivers consistently report issues with technical glitches, confusing app interfaces, and a lack of reliable support.

This guide provides actionable solutions for these common ELD truck driver elogs challenges. Instead of just listing problems, it offers a practical, solution-oriented framework for drivers and fleet managers. This article covers strategies for navigating complex HOS rules, handling technical failures, improving driver training, and finding a truly reliable ELD provider.

Do you have any questions? Talk to ELD Advisor: 650-405-3372 or Request Callback

1. Navigating HOS Rules with Elogs

The Challenge: Elogs Enforce Rules They Don’t Always Explain

Electronic logs are rigid. They strictly enforce HOS rules but don’t always make it easy to understand why a driver is running out of time. There is no “close call” when an app shows a violation.

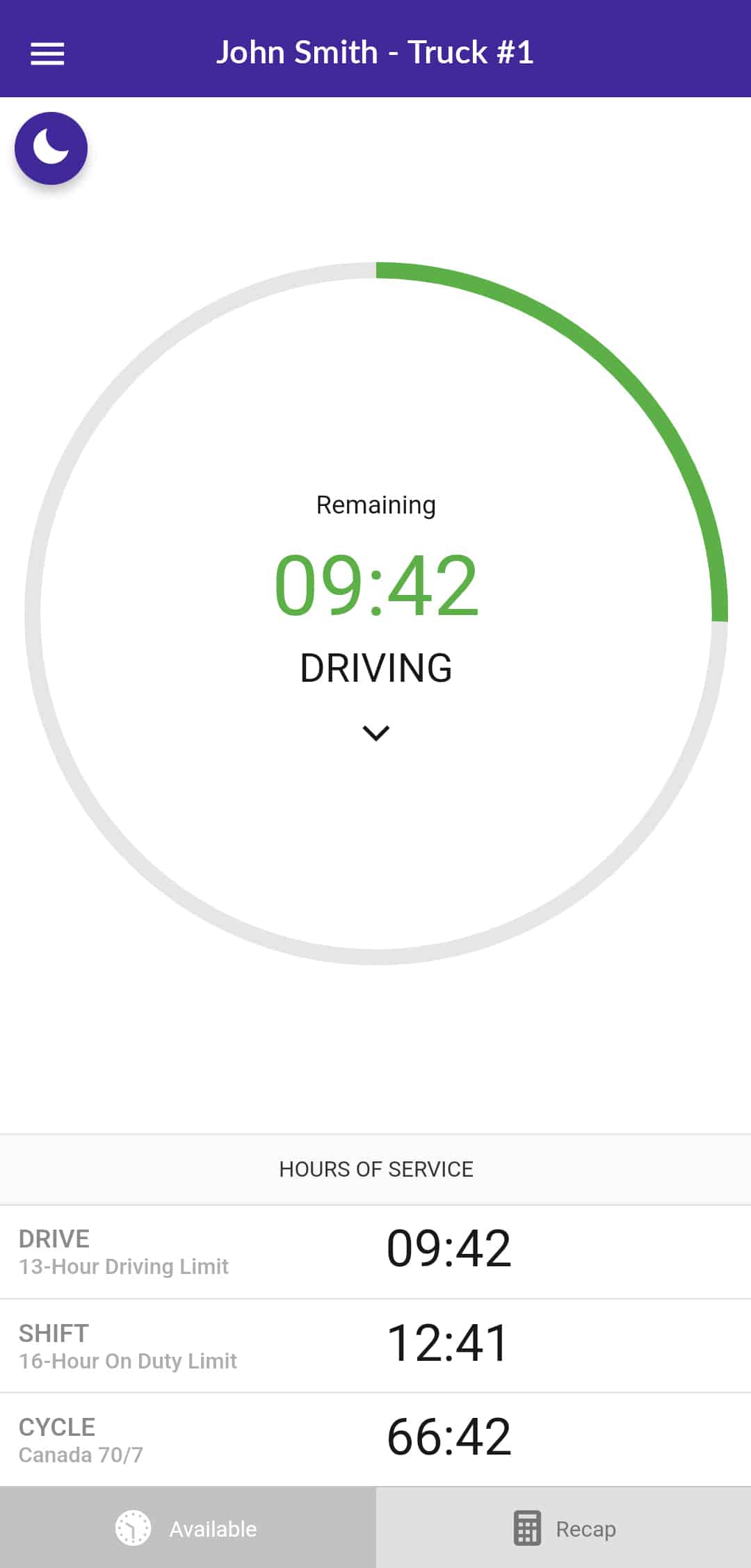

For drivers, confusion about the 13-hour driving limit, the 14-hour on-duty window, or when to take required off-duty time can lead to violations and stress. For fleet managers, these simple misunderstandings can result in penalties, out-of-service orders, and negative impacts on the company’s safety profile.

The Solution: Proactive Planning and Using Elog Tools

Managing HOS compliance is about more than just logging; it’s about planning. A good elog should be a tool for planning the day, not just a timer.

- Use scenario-based training. Instead of just rule memorization, training should focus on real-world scenarios. For example, “You are at a shipper, and your 14-hour window is still running. What are your options?” This is more effective than just reciting the rules.

- Plan the day with elog previews. Drivers should be trained to use the elog’s “hours remaining” or “recap” feature before starting a trip. Most systems can preview how a planned trip will impact their available hours, helping them spot a potential violation before they’re even on the road.

- Master special duty statuses. Properly using “Personal Conveyance” (PC) and “Yard Move” (YM) is critical. A clear company policy is essential. Drivers must understand that PC is for specific off-duty personal movements, and YM allows for moving a truck in a yard without starting the drive clock.

- Understand split-sleeper berth. The split-sleeper berth provision is a powerful tool for flexibility, but it’s also one of the most confusing HOS rules. A good elog system will have a clear interface to support it, but drivers need specific training on how the split 8/2 or 7/3 options pause and manage on-duty limits.

- Rely on automated alerts. Fleet managers should ensure the truck driver elogs automated alerts and warnings for approaching limits are enabled. These alerts act as a crucial final safety net to help drivers avoid a violation.

Ultimately, navigating HOS rules is about proactive strategy, not just reactive logging. When drivers are trained in real-world scenarios and use their driver elog as a daily planning tool, they can confidently manage their hours, required breaks, and special statuses. This approach turns the elog from a rigid enforcer into a helpful co-pilot, ensuring compliance and reducing stress on the road.

2. Managing Technical Reliability Concerns

The Challenge: Elog Malfunctions Create Compliance Risks

An elog that freezes, loses connectivity, or produces data errors is more than an annoyance. It is a critical compliance risk. When a device fails during a shift or, even worse, a roadside inspection, it can lead to missing logs and data corruption. This wastes valuable time and can jeopardize a driver’s HOS records, even when the driver has done nothing wrong.

The Solution: A Proactive Plan for Reliability

While no technology is perfect, a fleet can build a strong process to manage and minimize technical issues. This starts with choosing reliable hardware and includes having clear backup procedures for when a problem does occur.

- Practice preventive maintenance. Just like any other essential tool, ELD hardware should be inspected. Drivers and maintenance staff should regularly ensure that cables are secure, undamaged, and that port connections are clean.

- Maintain backup paper logs. Transport Canada requires drivers to carry a supply of paper logs. In case of an elog malfunction, drivers must immediately switch to paper logs to recreate their current and previous 14 days of HOS.

- Follow official malfunction reporting. Drivers must notify their carrier as soon as they identify a malfunction. A driver is permitted to use paper logs for no more than 14 days from the day the malfunction was noticed, or until they return to their home terminal (if the trip is longer than 14 days). The carrier must repair or replace the device within this timeframe.

- Train drivers on basic troubleshooting. Simple resets, like unplugging the device for a few seconds (if safe and not during driving), checking the app’s Bluetooth connection, or restarting the app, can often solve minor glitches.

- Choose reliable hardware. The best defense is prevention. When selecting a provider, look for high-quality, durable hardware with a proven, stable connection to the truck and the driver’s app.

- Document everything for inspections. During a roadside inspection with a malfunctioning device, the driver must be prepared to show the officer their current paper log and all supporting documentation.

Technical issues can happen, but they do not have to cause a compliance crisis. A clear strategy that includes dependable hardware, solid driver training on backup procedures, and proper reporting protocols ensures that operations and compliance stay on track.

3. Improving Driver Training and Adaptation

The Challenge: A Steep Learning Curve Can Cause Frustration

Implementing a new electronic logbook system involves a learning curve. Drivers with varying levels of comfort with technology must adapt quickly to a new workflow. Without a strong training plan, this transition period can lead to HOS errors, driver frustration, and resistance to the new system, which hurts both morale and productivity.

The Solution: A Structured and Ongoing Training Program

Successful elog adoption is an ongoing process, not a one-day event. The goal is to build driver confidence by making the technology approachable and providing support every step of the way.

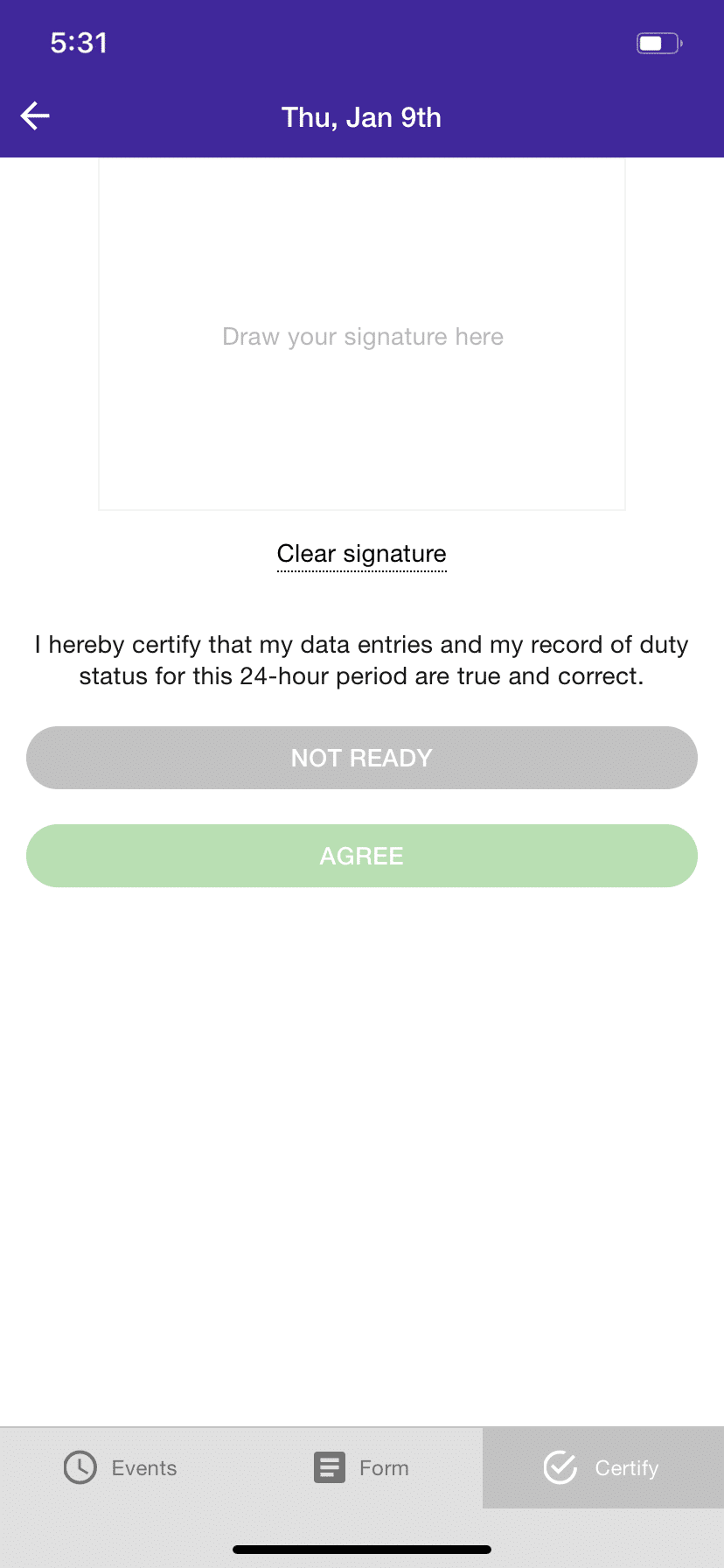

- Implement structured onboarding. A formal program that walks every driver through the system, from logging in to managing HOS, editing logs correctly, and performing a vehicle inspection report, ensures a consistent foundation of knowledge.

- Use driver mentorship. Identify tech-savvy drivers within your fleet to act as “elog advocates.” Drivers often learn best from a fellow driver who can share practical, on-the-job tips and build trust in the new system.

- Prioritize hands-on training. While classroom sessions are useful for HOS rules, nothing beats having a driver physically use the app. Hands-on practice in a test or training mode builds confidence and muscle memory for critical functions.

- Offer ongoing micro-learning. Keep knowledge fresh with short, 2-3 minute training videos or tips about specific features. This is highly effective for complex rules like split off-duty options or the correct use of yard moves.

- Create driver advocates. Involve drivers in the selection process. When drivers are part of the team that evaluates and chooses a new elog, they become advocates for its adoption rather than critics.

- Measure and reward success. Acknowledge drivers who maintain clean, violation-free logs or who actively help their peers. Positive reinforcement encourages successful adoption.

By creating a supportive learning environment with mentorship, hands-on practice, and continuous education, fleets can empower all drivers to become confident and efficient users of the technology.

4. Integrating Truck Driver Elogs with Existing Fleet Systems

The Challenge: Disconnected Systems Create Double the Work

An elog system shouldn’t operate on an island. When the ELD, dispatch software, and fuel card systems don’t communicate, it creates major inefficiencies. This can lead to compatibility issues, workflow disruptions for dispatchers, and drivers having to log into multiple apps or do duplicate data entry.

The Solution: A Phased and Validated Integration Strategy

The goal is to create a seamless flow of data where information from one system, like the ELD, automatically populates another, like dispatch or payroll. This requires a deliberate integration plan.

- Evaluate the API. An Application Programming Interface (API) is what allows different software systems to talk to each other. Before choosing an ELD, fleets should evaluate its API to ensure it can connect with their existing dispatch, TMS, or maintenance platforms.

- Map the data. Decide exactly what information needs to flow, and where. For example, HOS availability from the ELD should flow directly to the dispatcher’s planning screen.

- Use a phased approach. Instead of a complete, disruptive overhaul, integrate systems one at a time. Start with the most critical link, such as ELD-to-dispatch, get it stable, and then move on to the next one.

- Create unified workflows. The integration should result in a simpler, unified workflow for drivers and staff. A driver, for instance, should be able to manage their HOS and see load information in one place.

- Test before full implementation. Use a small, controlled test group of drivers and dispatchers to run the integrated system. This helps find and fix bugs before a full-fleet rollout.

- Communicate with all stakeholders. Keep drivers, dispatchers, and maintenance crews informed about the transition, what to expect, and what new, simpler workflows will look like.

A well-integrated system saves time, reduces errors, and gives dispatchers the real-time HOS data they need to assign loads efficiently and legally.

5. Maximizing ROI Beyond Compliance

The Challenge: Viewing the Elog as Only a Compliance Cost

Many fleets view the ELD as a mandatory, sunk cost required by Transport Canada. This perspective overlooks the immense amount of valuable data the device collects from the truck’s engine. When this data is underutilized, fleets miss significant opportunities for operational improvements and cost savings.

The Solution: Using Elog Data as a Business Intelligence Tool

A modern ELD is a powerful data-gathering device. By shifting the perspective from a simple logbook to a business intelligence tool, fleets can unlock a substantial return on their investment.

- Improve fuel efficiency. The ELD captures data on driving behaviors like hard braking, rapid acceleration, and idling time. This information can be used to coach drivers and reduce fuel waste.

- Enable proactive maintenance. By reading fault codes directly from the engine, an ELD can alert fleet managers to potential maintenance issues in real time. This helps schedule repairs before a small problem leads to a costly breakdown.

- Enhance driver coaching. ELD data provides objective insights into driver performance, HOS management, and safety patterns. This allows for specific, data-driven coaching to help drivers stay safe and compliant.

- Optimize routes. Historical trip data, combined with GPS tracking, helps managers analyze route efficiency, identify common delay spots, and plan better, more profitable routes.

- Improve customer service. Real-time GPS tracking, combined with accurate HOS data, allows dispatchers to provide customers with highly accurate ETAs.

- Enhance safety programs. Analyzing elog violation patterns across the fleet can highlight areas where more training is needed, allowing managers to proactively address safety risks.

When viewed as a data hub, the elog transforms from a compliance expense into a strategic asset that can improve fuel economy, reduce downtime, and enhance safety.

6. Improving Driver Satisfaction and Retention

The Challenge: When Elogs Contribute to Driver Frustration

For drivers, a poorly implemented elog system can feel like a micromanagement tool that adds stress. Inflexible hour tracking, constant alerts, and systems that are hard to use can contribute to driver frustration. When this frustration is added to compensation concerns or dispatch conflicts, it can become a key factor in driver turnover.

The Solution: Using Elogs to Build Trust and Improve Quality of Life

A good elog system, when paired with a supportive company culture, can actually improve the driver’s experience. This is achieved by using the technology to enhance safety and transparency rather than surveillance.

- Use recognition, not just correction. Create programs that recognize drivers for maintaining clean, violation-free logs. Positive reinforcement for good HOS management is more effective than only focusing on violations.

- Emphasize safety over surveillance. Communications about elog data should always be framed around safety and compliance. This builds trust and shows that the goal is to protect the driver and the company, not to micromanage.

- Create driver feedback loops. Actively ask drivers for feedback on the elog system. Are there features that are confusing? Is the hardware inconvenient? This feedback is essential for system improvements.

- Train dispatchers on elog constraints. Dispatchers must be trained to work with the electronic logbook, not against it. They need to understand a driver’s available HOS and plan loads that are realistic and compliant, reducing driver stress.

- Involve drivers in elog selection. As mentioned in the training section, involving drivers in the evaluation and selection process is critical. When drivers help choose the tool, they are far more likely to be satisfied with it.

When drivers feel the elog system is a tool that helps them stay safe and compliant — rather than one that punishes them — it becomes a positive part of the work environment, not a reason to leave.

7. Finding a Reliable Elog Provider

The Challenge: A Saturated Market with Hidden Problems

The ELD market is crowded, and many offerings look the same. It is difficult for fleet managers to compare technical specifications, identify hidden costs, or know what level of customer support they will actually receive. Choosing the wrong provider often leads to long, expensive contracts, poor reliability, and non-existent support.

The Solution: A Diligent Selection and Trial Process

Choosing a provider should be treated as a long-term partnership, not a simple purchase. The focus should be on reliability, support, and transparency.

- Prioritize a trial or pilot program. This is the most important step. Use the trial period to test everything: hardware reliability in your specific trucks, app ease-of-use for your drivers, and the support team’s response time and knowledge.

- Scrutinize the contract. Look for hidden fees, auto-renewing clauses, and high termination penalties. A provider that is confident in its product will offer flexible or no-contract options.

- Benchmark customer support. Call the support line at different times of day, including a night or weekend. Is it a long hold? Do you get a call center or a knowledgeable representative? This is a crucial test.

- Calculate the total cost of ownership. The cheapest per-month price is rarely the cheapest total cost. Factor in hardware costs, installation fees, and potential costs for upgrades or integrations.

- Watch for red flags. Be wary of high-pressure sales tactics, providers who won’t offer a trial, or reviews that consistently mention “hidden fees” or “no support.”

Finding a reliable provider is the foundation for solving almost every other challenge. A dependable partner provides reliable hardware, an easy-to-use app, and the support to back it up.

HOS247: A Quality Solution for Truck Driver Elog Challenges

Solving the seven key elog challenges requires a provider focused on reliability, ease of use, and outstanding support. HOS247 is a top-rated provider known for its dependable, Transport Canada–compliant platform designed to address the most common driver and fleet manager frustrations.

The system provides a complete, integrated solution that directly addresses the issues discussed. Here’s how HOS247 ELD system helps truckers address elog challengers:

- Clear HOS navigation. The HOS247 driver app is intuitive and easy to use. It simplifies HOS management, making it simple for drivers to see remaining hours, manage breaks, and correctly use special statuses like split-sleeper berth or yard move.

- Technical reliability. The system is built on durable, high-quality hardware and a stable Bluetooth connection. This focus minimizes the data errors, connectivity issues, and frozen screens that cause inspection delays.

- Faster training and support. The user-friendly design significantly reduces the learning curve. This is backed by a top-rated, multilingual support team, ensuring drivers and managers can get a quick, clear answer from a live person in English, Spanish, Polish, or Russian.

- Easy system integration. A flexible API is available, allowing fleets to connect HOS247 data with their existing dispatch, TMS, and maintenance software for a unified, efficient workflow.

- Full ROI potential. The platform includes real-time GPS tracking, vehicle diagnostics with fault code alerts, and idling monitoring. This turns the elog into a powerful tool for proactive maintenance, fuel-saving, and route optimization.

A Focus on Reliability and Transparency

The HOS247 hardware, software, and support are designed to work together as a single, resilient ecosystem. This dependable service is offered through flexible, no-contract plans. This policy gives fleets the freedom to scale as needed and ensures HOS247 is focused on earning their business every month through quality and service, not long-term contracts.

With a direct-access support model, transparent pricing, and automatic compliance updates, the platform is built to be a dependable, long-term partner for fleets of all sizes.

Conclusion: A Strategic Approach to Driver Elog Management

Managing driver elog challenges effectively goes far beyond the device itself. It involves a comprehensive strategy for navigating HOS rules, ensuring technical reliability, providing continuous driver training, and integrating data systems.

As this guide has shown, these problems are best solved with proactive, long-term solutions, not temporary fixes. The ultimate goal is to create a system that balances unwavering compliance with operational excellence, allowing your business to thrive.

This balance is easiest to achieve when fleets are supported by reliable technology from a partner that understands the complete landscape of the trucking industry. By carefully evaluating a provider’s reliability, support structure, and true long-term value, fleet managers can make an informed decision and turn their elog system from a mandatory requirement into a powerful operational advantage.

As an expert in B2B and B2C sales, I’ve dedicated myself to perfecting sales processes and client retention strategies in the logistics and trucking industry. I have significantly contributed to the expansion of the ELD service, catering to retail and wholesale clients in need of HOS247 ELD solutions. My unwavering commitment to implementing state-of-the-art sales techniques and technologies ensures the continuous growth and success of businesses I work with.

The world of trucking has come a long way since the days of paper maps and CB radios. Technology has revolutionized how fleets operate, and GPS tracking is at the forefront of this transformation. 4G vehicle tracking systems are reshaping

For truck owners and carrier companies in Canada, logistics is always a priority. This is where real-time tracking of commercial vehicles can offer multiple benefits, including increased productivity and enhanced security. Before going into the advantage of live truck tracking

Behind every successful transportation business is the ability to monitor, track, and optimize asset use. Trailer track systems, powered by advanced technologies, have become indispensable tools for achieving this, as they provide a holistic view of operations. This article delves